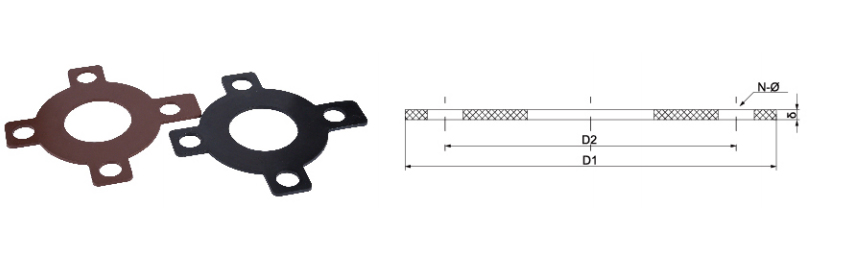

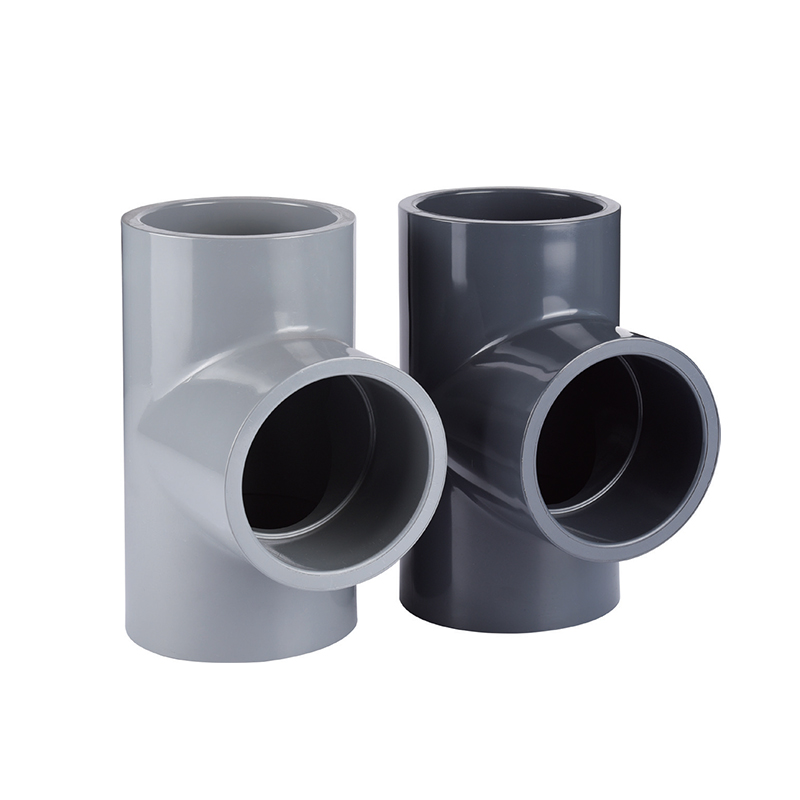

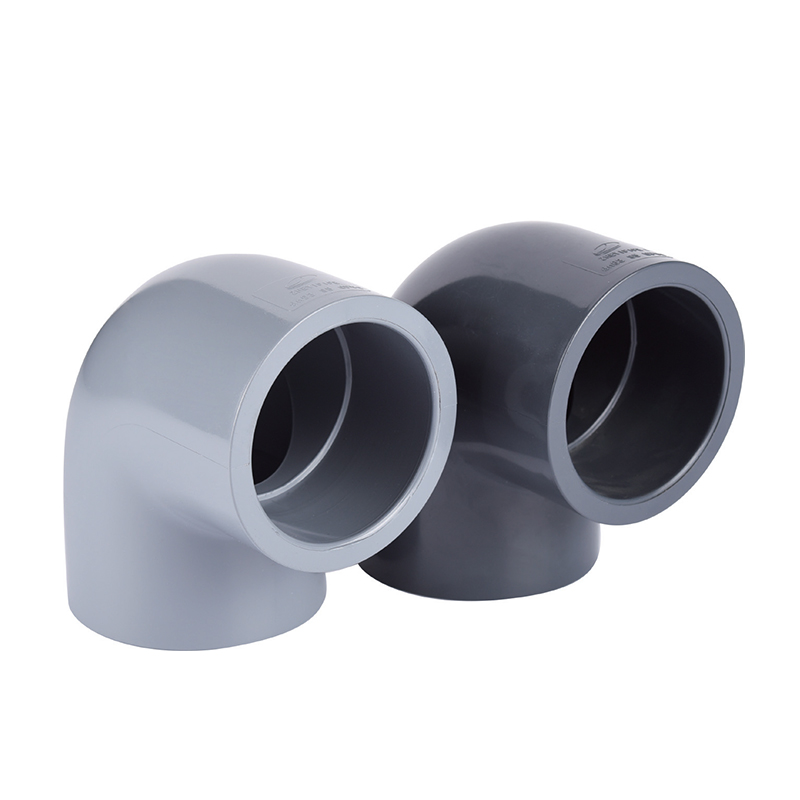

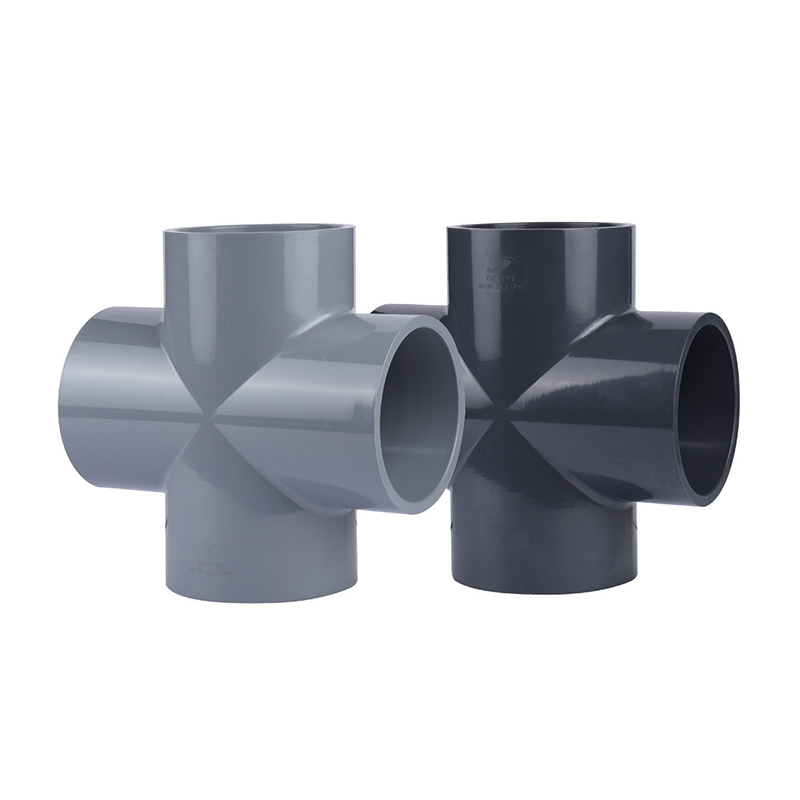

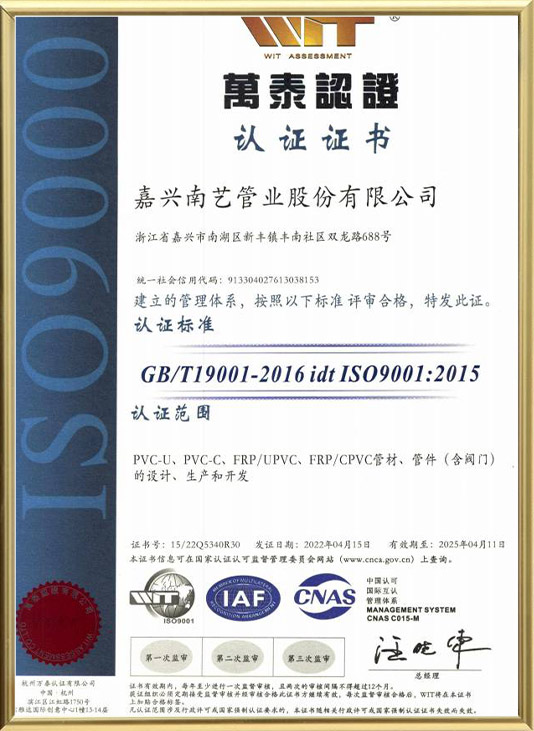

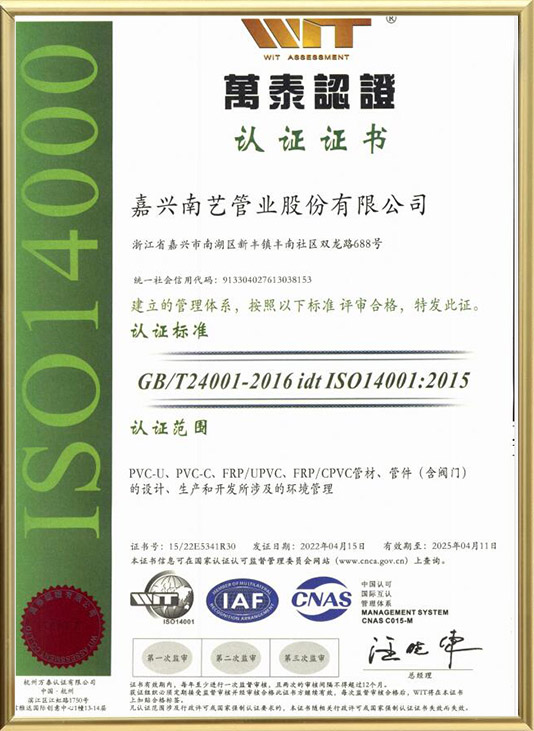

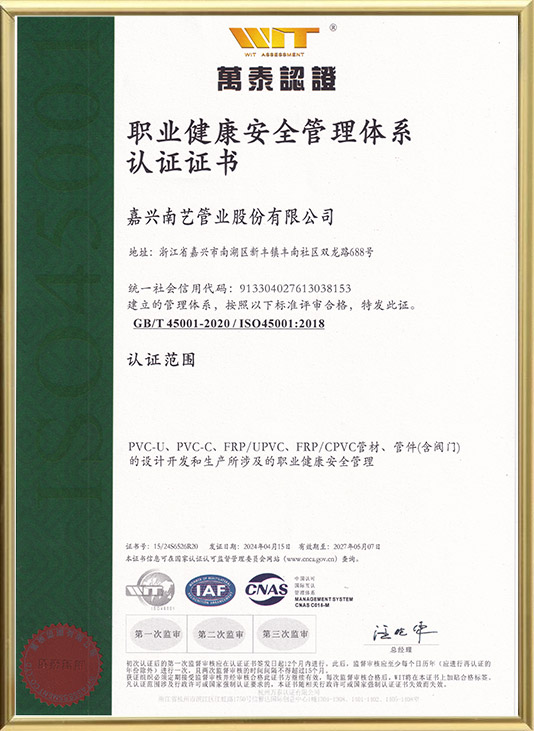

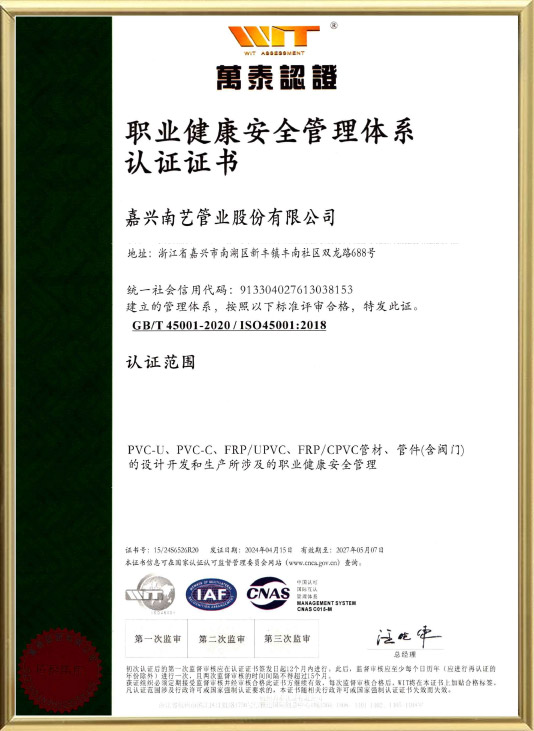

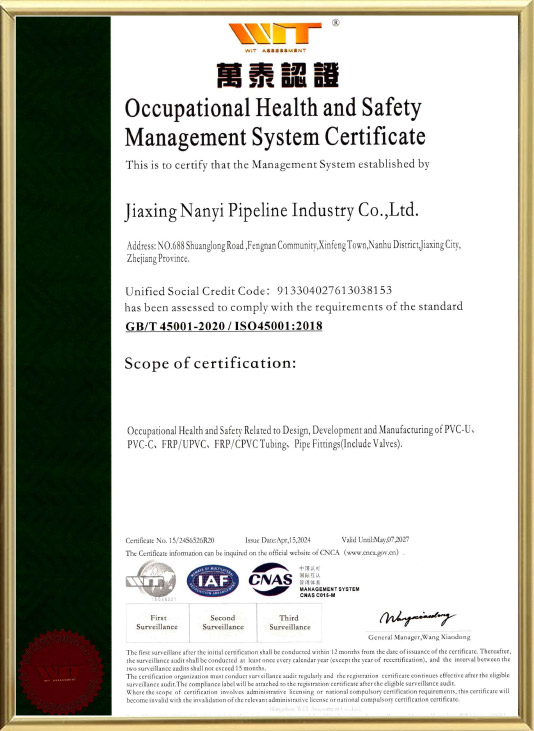

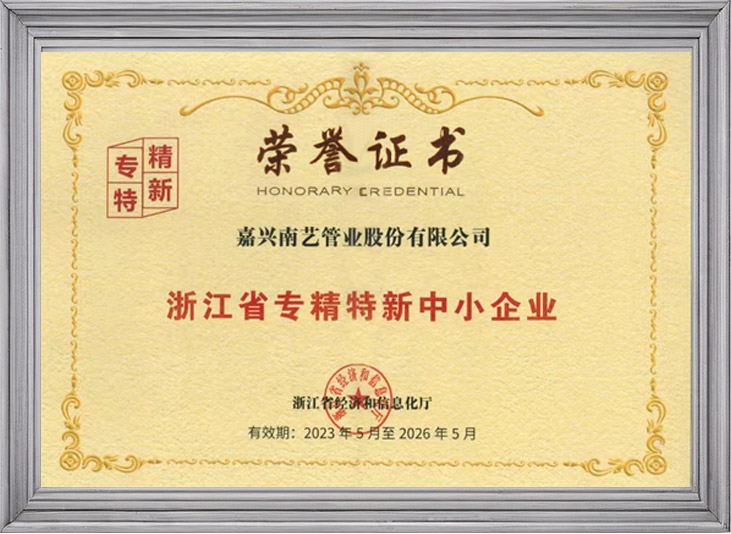

ZHEYI Group oo Tsina SCH8O/DIN UPVC/CPVC Flange Gasket Para sa industriya ng pagkain/automotiko/elektronik tagapagtustos at pasadyang ginawa SCH8O/DIN UPVC/CPVC Flange Gasket Para sa industriya ng pagkain/automotiko/elektronik pabrika. Kami ay itinatag noong 2007, na nakatuon sa pananaliksik at pagpapaunlad, pagmamanupaktura, pagbebenta at serbisyo ng CPVC at UPVC na mga pang-industriyang tubo. Ang kumpanya ay nakakuha ng ilang mga sertipikasyon, kabilang ang espesyal na lisensya sa produksyon ng kagamitan, ang Zhejiang Province na may kaugnayan sa tubig na lisensya sa kalinisan ng produkto, ang IS09001 na sertipikasyon ng sistema ng pamamahala ng kalidad, ang sertipikasyon ng sistema ng pamamahala sa kapaligiran ng IS014001, at ang sertipikasyon ng sistema ng pamamahala sa kalusugan at kaligtasan ng trabaho sa IS045001. Ang kumpanya ay may higit sa 50 independiyenteng mga karapatan sa intelektwal na ari-arian at self-operated na mga karapatan sa pag-import at pag-export. Upang makapagbigay ng sari-saring produkto at mas mahusay na serbisyo, ipinakilala ng kumpanya ang advanced na teknolohiya, kagamitan sa tooling, at natatanging mga hilaw na materyales at sistema ng pamamahala mula sa Germany at United States. Sa paglipas ng mga taon, ang aming mga produkto ay malawakang ginagamit sa pipeline na transportasyon ng mga acid at alkali na likido, ultrapure na tubig, inuming tubig, electronic grade purong tubig, at pang-industriyang wastewater sa kemikal, metalurhiko, photovoltaic, nuclear power, lithium battery, electronic semiconductor, pagkain, gamot, sasakyan, pang-industriya na paggamot ng tubig at iba pang mga industriya. Sa kasalukuyan, ang ZHEYI Group ay nagtatag ng higit sa 30 mga kumpanya ng pagbebenta sa buong bansa, at lahat ng uri ng mga produkto ay ini-export sa Europa, Amerika, Timog-silangang Asya at iba pang mga bansa at rehiyon, at lubos na pinapaboran ng mga domestic at dayuhang customer.

Pangkalahatang-ideya ng CPVC flanged ball valve Mga Application at Mga Kinakailangan sa Pag-install Ang CPVC flanged ball valve ay malawakang ginagamit sa mga pang-industriyang pipeline system na huma...

matuto pa +86-15258772971

+86-15258772971

dinys009@163.com

dinys009@163.com